Struggling to balance cutting costs with quality? Choosing the wrong technology can drain your budget and slow down production, impacting your bottom line every single day.

Fiber laser offers unmatched speed and precision on thinner metals with lower running costs. Plasma remains the economical champion for cutting thick, heavy plates where initial investment is a key factor. The best choice depends entirely on your primary application and long-term goals.

This decision goes beyond just the initial price tag. In my years of experience helping workshops like yours, I've learned that the real answer lies in the total cost of ownership and how each machine fits into your entire production line. Let's break it down.

Which technology truly costs less in the long run, laser or plasma?

Worried about high energy bills and constant consumable changes? These operational costs can quietly eat into your profits, making a cheap machine expensive over time.

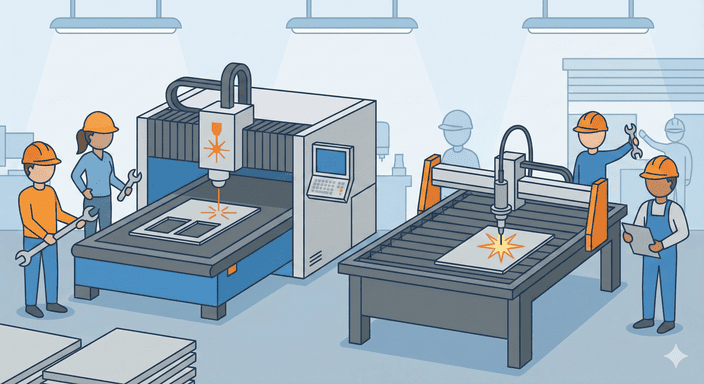

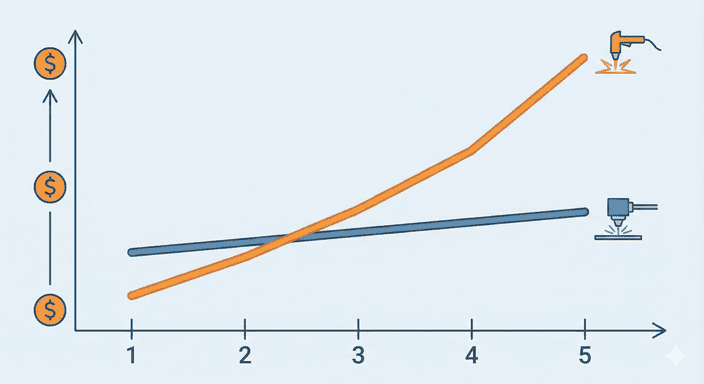

Fiber lasers win on long-term operational costs. They have higher electrical efficiency and very few consumables. Plasma systems are cheaper upfront but require regular replacement of parts and use more power, increasing the cost-per-part over the machine's lifetime.

When I talk with Production Directors, the conversation often starts with the purchase price. Plasma is almost always cheaper to buy. But the real story is in the Total Cost of Ownership (TCO). A few years ago, the math was simple. Today, it’s different. The fiber laser’s efficiency has changed the game. Think about your daily expenses. A plasma cutter needs a steady supply of consumables like electrodes and nozzles. A fiber laser doesn't. Its power source, the laser diodes, can last for over 100,000 hours with almost no maintenance. This means less downtime and fewer surprise bills. It also uses significantly less electricity to produce the same cutting power. For a shop running high-volume jobs on material under 12mm, these savings add up fast, often making the laser the cheaper option over five years.

Key Cost Factors

| Cost Factor | Fiber Laser | High-Definition Plasma |

|---|---|---|

| Initial Investment | High | Low to Medium |

| Consumables | Very Low (nozzles, lenses) | High (electrodes, nozzles, shields) |

| Electrical Efficiency | High (around 30-40%) | Low (around 15-20%) |

| Maintenance | Minimal (no alignment needed) | Regular (torch maintenance) |

How much difference in cut quality and precision can you expect?

Are secondary operations like grinding and deburring killing your productivity? Poor cut quality creates extra work, slowing down your entire workflow and increasing labor costs.

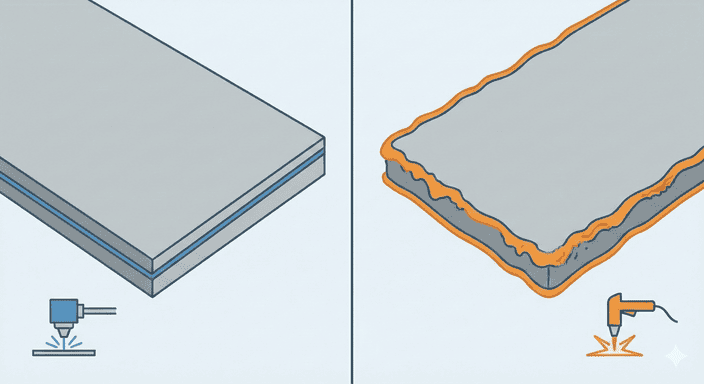

Fiber laser delivers superior precision, often achieving tolerances of ±0.03mm with a very small heat-affected zone (HAZ). This means clean, sharp edges that need little to no finishing. High-definition plasma is good, but typically produces more taper and requires post-cut cleanup.

I once visited a facility that made intricate parts for the automotive industry. They were using a plasma cutter, and a team of three people spent their entire day grinding dross off the finished parts. That's a huge hidden cost. When they switched to a fiber laser, that secondary process was almost completely eliminated. The laser's focused beam creates a much smaller kerf (the width of the cut) and puts very little heat into the material. This small Heat-Affected Zone (HAZ) is critical. It means less warping and cleaner holes, especially on stainless steel and aluminum. For shops where precision is everything, the laser is in a class of its own. It allows you to produce parts that are ready for welding or assembly right off the table, which dramatically speeds up the entire production cycle.

Precision and Finish Comparison

| Feature | Fiber Laser | High-Definition Plasma |

|---|---|---|

| Typical Precision | ±0.03mm | ±0.2mm |

| Heat-Affected Zone (HAZ) | Very Small | Moderate |

| Edge Taper | Minimal | Noticeable |

| Dross on Thin Steel | None | Minimal to Moderate |

Where is the real performance sweet spot for each technology?

Is your current machine a bottleneck? Using the wrong cutter for the job means either slow production on thin sheets or struggling with thick plates.

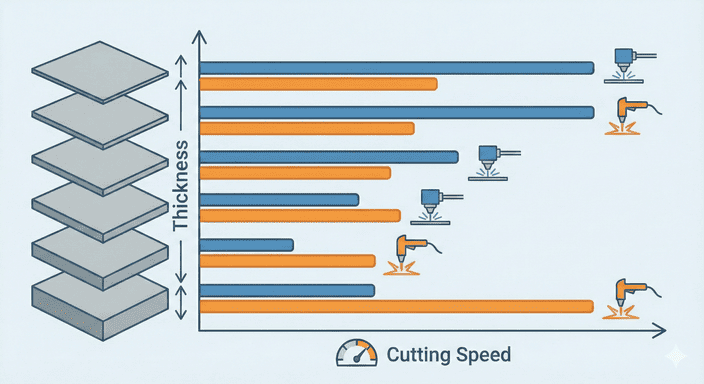

Fiber laser is unbeatable for speed on materials under 20mm. Its velocity is huge. For thick plates, especially carbon steel over 30mm, high-definition plasma is often faster and more cost-effective, as the laser's speed advantage drops off significantly.

Marketing materials can be misleading. They show a laser cutting thick plate, but they don't always tell you how slow it is. You have to find the "sweet spot" for your own production. I always tell my clients to analyze their most common jobs. If you spend 80% of your time cutting 10mm stainless steel, a fiber laser will pay for itself in speed alone. The cutting speeds can be five to ten times faster than plasma in that range. But if your main business is cutting 50mm carbon steel for heavy structures, a high-power plasma system is the workhorse you need. At that thickness, the laser slows down dramatically, and the plasma cutter becomes the more economical and practical choice. It's about matching the tool to the task, not just buying the newest technology.

Optimal Thickness Ranges

| Material Type | Fiber Laser "Sweet Spot" | Plasma "Sweet Spot" |

|---|---|---|

| Carbon Steel | Up to 20mm | 30mm to 80mm+ |

| Stainless Steel | Up to 15mm | Over 20mm |

| Aluminum | Up to 12mm | Over 15mm |

What about versatility and long-term strategic fit?

Can your cutting machine adapt to new jobs and materials? A machine that only does one thing well can limit your shop's growth and ability to compete.

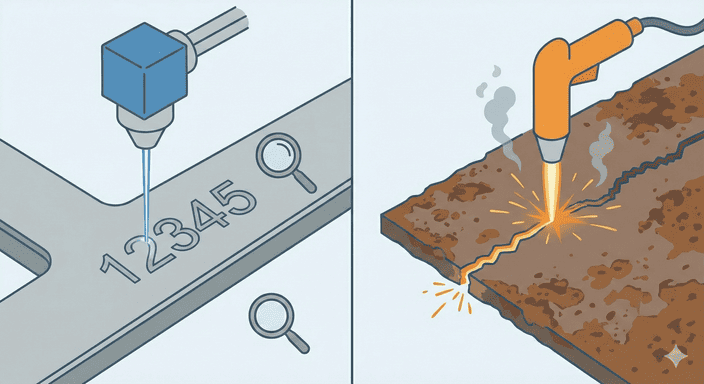

Fiber lasers offer better versatility for complex parts, fine details, and marking. Plasma has an edge with imperfect materials like rusty or painted plate. Strategically, lasers support automation and precision manufacturing, while plasma remains essential for heavy structural work.

I worked with a production manager who was frustrated because his laser would often fail to cut when it hit a patch of rust or a painted surface. The laser beam needs a clean, consistent surface to work effectively. For his work in ship repair, a plasma cutter was a much better fit. It simply powers through surface imperfections. On the other hand, another client who runs a contract manufacturing shop loves his fiber laser because it's not just a cutter. He can use the same machine to etch part numbers and logos, which adds value for his customers. When you think strategically, you have to consider what kind of work you want to attract in the future. Are you moving towards high-precision, automated production lines? The fiber laser integrates perfectly. Are you focused on being the most cost-effective provider for heavy plate fabrication? Plasma is your reliable foundation.

Strategic Application Fit

| Capability | Fiber Laser | High-Definition Plasma |

|---|---|---|

| Handling Imperfect Materials | Poor (reflection issues) | Excellent |

| Complex Geometries/Small Holes | Excellent | Good |

| Marking/Etching | Yes | No |

| Best for Automation | High-precision assembly lines | Heavy structural fabrication |

Conclusion

Choosing between fiber laser and plasma is a strategic decision. Your material thickness, required precision, and long-term business goals will ultimately guide you to the right investment for your shop.